As a widely used device in modern architecture, the service life, wear resistance, and durability of automatic door openers directly impact their overall performance and user experience. With the advancement of technology, the design and manufacturing techniques of automatic door openers have also continuously improved to meet market demands for high-performance and high-reliability products. This article delves into the service life, wear resistance, and durability of automatic door openers, analyzing these aspects from the perspectives of technical principles, material selection, manufacturing processes, and maintenance.

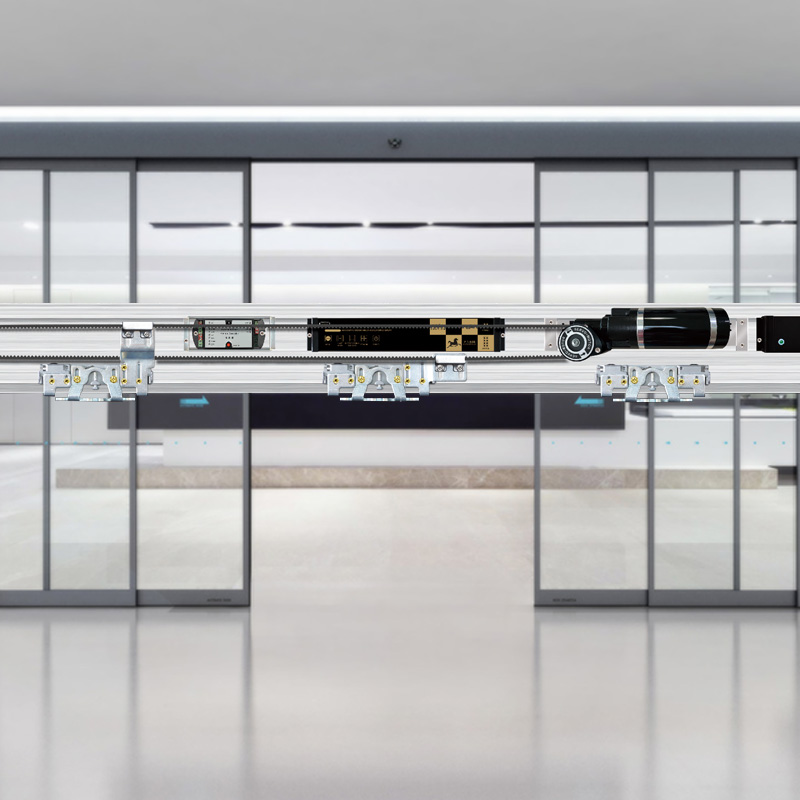

Automatic door openers primarily operate by detecting the approach of people or objects through sensing devices, triggering the door-opening action. The main components of a typical automatic door opener include:

1. Sensing Device: Such as infrared sensors or radar sensors, responsible for detecting approaching targets.

2. Controller: Receives sensing signals and issues door-opening commands.

3. Drive Unit: Typically a motor, which drives the door to open and close.

4. Transmission System: Including belts, chains, and gears that transfer the motor's power to the door.

5. Door and Track System: The door moves smoothly along the track system.

The service life of an automatic door opener refers to the duration it can maintain good working condition under normal usage and maintenance. The factors affecting the service life of automatic door openers include the following:

The quality of materials directly determines the durability and service life of the opener. High-quality materials not only improve the strength and wear resistance of the opener but also prevent deformation and damage over time.

· Metal Materials: The transmission components of automatic door openers often use high-strength metals like steel and aluminum alloys. These materials possess excellent mechanical strength and wear resistance, capable of withstanding frequent opening and closing operations.

· Plastic Materials: Some parts, such as the sensor housing and controller housing, may use high-strength engineering plastics. These plastics have good weather resistance and impact resistance, suitable for various environmental conditions.

Advanced manufacturing processes can enhance the overall quality and durability of automatic door openers. The quality of the manufacturing process directly impacts the precision of the components and the assembly quality.

· Precision Machining: Precision mechanical processing ensures the dimensional accuracy and surface quality of components, improving the transmission system's smooth operation and wear resistance.

· Heat Treatment: Heat treatment processes like quenching and tempering can increase the hardness and wear resistance of metal parts, extending their service life.

· Surface Treatment: Surface coatings and oxidation treatments can improve the corrosion resistance and wear resistance of components, preventing rust and wear.

Rational design significantly improves the service life and reliability of automatic door openers.

· Structural Optimization: Optimized design ensures uniform force distribution across components, reducing stress concentration and fatigue damage.

· Redundant Design: Redundant design in critical components enhances system reliability and fault tolerance.

· Sealing Design: Sealing design in key areas prevents dust, moisture, and other contaminants from entering, protecting components from damage.

The usage environment greatly affects the service life of automatic door openers. Harsh environmental conditions may accelerate equipment aging and damage.

· Temperature and Humidity: Extreme temperature and humidity conditions can lead to material performance degradation and increased component wear.

· Dust and Pollution: Dust and pollutants can enter the transmission system and controllers, affecting normal operation.

· Chemical Corrosion: Certain environments with chemical substances may cause corrosion to the equipment materials, shortening the service life.

Regular maintenance is crucial for extending the service life of automatic door openers.

· Regular Inspections: Periodic checks on the transmission system, controller, and sensors can identify and address potential issues promptly.

· Lubrication Maintenance: Lubricating the transmission system reduces friction and wear, enhancing operational smoothness.

· Cleaning Maintenance: Regular cleaning of the equipment surface and internal parts prevents dust and contaminants from accumulating, ensuring normal operation.

The wear resistance and durability of components are crucial factors that impact the overall performance and service life of automatic door openers. The following analyzes the wear resistance and durability of several key components:

The motor is the core drive unit of the automatic door opener, and its performance and durability directly determine the opener's efficiency and service life.

· Motor Type: Common motor types include DC motors and AC motors. DC motors feature quick startup and easy speed control but require regular brush replacement. Brushless DC motors and AC motors have longer service lives and lower maintenance costs.

· Motor Wear Resistance: The wear resistance of the motor mainly lies in the bearings and rotor components. High-quality bearings and rotor materials can significantly improve motor wear resistance and service life.

· Heat Dissipation: Good heat dissipation design prevents motor overheating, extending the motor's service life.

The transmission system is one of the most wear-prone components of automatic door openers. Its wear resistance and durability directly affect the smooth operation of the device.

· Belts and Chains: The transmission belts and chains are key components of the transmission system. High-strength wear-resistant materials and precise manufacturing processes can improve their wear resistance and service life.

· Gears: The gear transmission system requires high-precision machining and surface treatment to enhance gear wear resistance and fatigue resistance.

· Lubrication System: Regular lubrication reduces friction and wear in the transmission system, extending the service life of components.

The controller and sensors are the control cores of automatic door openers. Their reliability and durability directly impact the normal operation of the device.

· Electronic Components: The controller's internal electronic components need to have high reliability and long life. Using high-quality components and stringent quality control can improve the controller's durability.

· Sensors: The durability of sensors mainly lies in their housings and internal electronic components' environmental resistance. Waterproof and dustproof designs can enhance the sensors' service life.

To better understand the service life, wear resistance, and durability of automatic door openers, here are several specific case studies:

A large shopping mall installed dozens of automatic doors, with a daily foot traffic of tens of thousands of people. These automatic door openers use high-strength aluminum alloy materials and brushless DC motors, providing good wear resistance and long life.

· Service Life: After years of use, these automatic door openers still operate stably, exceeding expected service life.

· Maintenance: The mall management regularly inspects and maintains the automatic doors, promptly replacing worn parts to ensure normal operation.

Automatic door openers installed at a hospital's emergency room entrance need frequent opening and closing. These openers use high-quality steel gears and chain transmission systems to improve durability.

· Service Life: Despite frequent use, these automatic door openers meet design standards for service life without major faults.

· Wear Resistance: The steel gears and chains exhibit excellent wear resistance, maintaining good working condition after prolonged use.

Automatic door openers in an industrial plant need to work in high-temperature, high-humidity, and dusty environments. These openers are designed with waterproof and dustproof features and made of high-temperature-resistant materials.

· Service Life: Despite the harsh working environment, these automatic door openers meet expected service life.

· Durability: The waterproof and dustproof design effectively protects internal components, extending the equipment's service life.

With continuous technological advancements, the design and manufacturing techniques of automatic door openers are constantly innovating. In the future, the service life, wear resistance, and durability of automatic door openers will further improve, mainly in the following aspects:

The application of new materials will significantly enhance the wear resistance and durability of components. For instance, nanomaterials and polymer composites will gradually be used in manufacturing automatic door openers, improving the overall performance of the equipment.

Intelligent design will improve the reliability and maintenance convenience of automatic door openers. For example, IoT-based remote monitoring and fault diagnosis technology can monitor equipment status in real-time, promptly identifying and addressing potential issues to extend the equipment's service life.

With increasing environmental awareness, automatic door openers will focus more on energy-efficient design and the use of environmentally friendly materials. For example, high-efficiency motors and low-power controllers will reduce energy consumption, while environmentally friendly materials will minimize environmental impact.

The service life, wear resistance, and durability of automatic door openers are critical indicators for evaluating their overall performance. By selecting appropriate materials, utilizing advanced manufacturing processes, and employing scientific design, the durability and reliability of automatic door openers can be significantly improved. Regular maintenance is also essential for extending the service life of the equipment. With ongoing technological advancements, the performance of automatic door openers will further improve, providing users with more stable and reliable experiences.