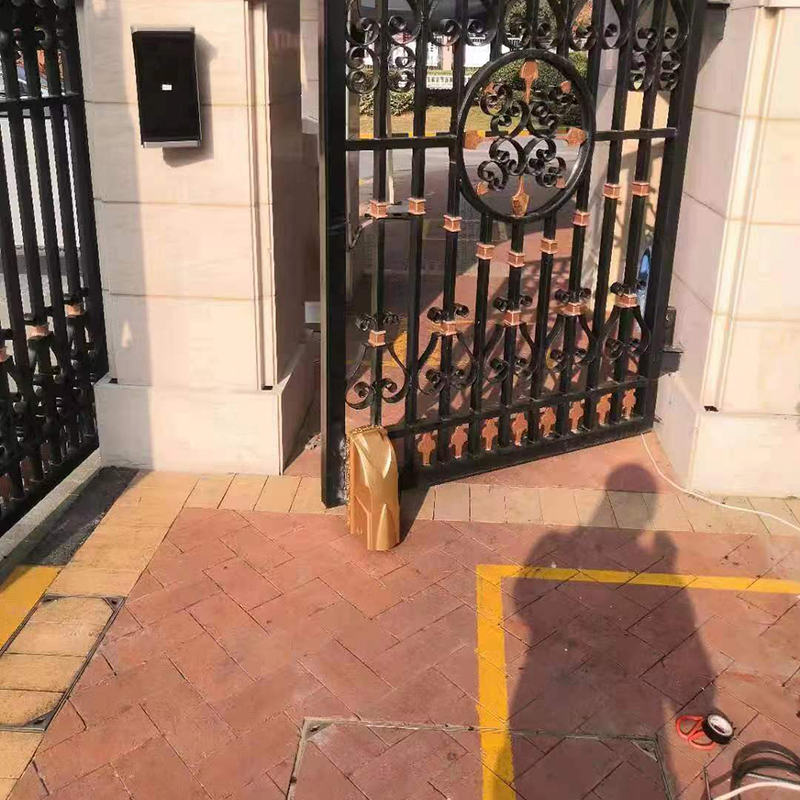

Automatic gate openers offer a blend of convenience and security for homeowners and businesses alike. However, given the high levels of force these systems use to move gates, safety is a paramount concern. Manufacturers of automatic gate openers are well aware of these risks and have implemented a series of measures to ensure the safety and reliability of their products during the manufacturing process. This article will delve into the key safety measures taken to protect users from potential hazards.

Adherence to Safety Standards

One of the first lines of defense in ensuring safety is adherence to established safety standards. Two of the most recognized standards in the industry are UL325 and ASTM F2200. UL325, developed by Underwriters Laboratories, addresses the manufacturing and installation of gate openers, while ASTM F2200 focuses on the design and construction of gates intended for automation, particularly for vehicular traffic.

Design and Construction

During the design phase, manufacturers incorporate safety features such as covers for all exposed rollers, protective screen mesh, and guard posts to prevent entrapment or pinch points. Slide gates and adjacent fences are designed to prevent a 2 1/4” sphere from passing through up to 48” from the ground, ensuring that small objects and children cannot pass through, reducing the risk of entrapment.

Safety Devices

Automatic gate openers are equipped with a variety of safety devices to prevent injury or damage in the event of an obstruction. These include gate sensing edges, photoelectric sensors, and audio/visual alarms that detect obstacles and stop the gate from closing. Manufacturers ensure these devices are integrated into the system and tested rigorously to meet the requirements of UL325.

Manual Operation Safety

In the event of a power outage or system failure, gate openers are designed to be manually operated. Manufacturers provide clear instructions on how to safely perform this operation, emphasizing the need to turn off all electrical power before attempting manual control.

Quality Control and Testing

Throughout the manufacturing process, quality control checks are conducted to ensure that each component meets the required safety specifications. This includes regular testing of the gate openers under various conditions to simulate real-world scenarios. Manufacturers also provide maintenance schedules and guidelines to ensure that the gate systems continue to operate safely over time.

Installer Training and Certification

Manufacturers often require that installers be trained and certified to ensure that gate openers are installed correctly and in accordance with safety standards. This training covers the proper use of safety devices, identification of entrapment zones, and the correct installation of protective guards.

User Education and Warning Signs

Manufacturers also recognize the importance of educating the end-user about the safe operation of automatic gates. This includes providing safety brochures, warning signs, and clear instructions on the use and maintenance of the gate system. Warning signs are recommended to be displayed on both sides of the gate to alert users and pedestrians of potential hazards.

Conclusion

The safety and reliability of automatic gate openers are ensured through a combination of rigorous design standards, the integration of safety devices, quality control measures, and proper installation and maintenance. By adhering to these measures, manufacturers can significantly reduce the risk of injury or death associated with the use of automatic gate systems, providing users with a secure and convenient access solution.